Many industrial processes take place in reactors or tanks that are built to ANSI, DIN, or other standards that incorporate circular flange

connections. For observation into such process chambers or boilers, sight glasses mounted onto flange connections are ideal.

PPC offers three such flange mounted sight glass windows designs: the very simple Model S, the more advanced X150,

and the Model L for applications that require forgings/certifications. ANSI dimensions are default; DIN or other standards can be specified.

Unit Price Starting from $132.00

Model S Flange Details |

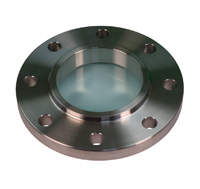

Model S Flange: Lowest Initial Acquisition Cost

For the lowest initial acquisition cost, choose our Model S sight glass. The Model S sight glass is an industry cost leader.

It features a simple tempered Pyrex or soda lime glass lens bonded to a modified ANSI flange.

Since the glass is bonded to the retaining flange at the factory, installation is a simple one-man job. It is supplied with a sealing gasket that is cut to the inner ANSI flange bolt circle diameter for easy centering. This model is comparable in performance to competitor's products, and it seals with a sealing gasket on the face of the glass lens. For the Model S (and all other sight glass windows that seal on the face of the glass), lens and sealing gaskets should be replaced periodically BEFORE there is an obvious sign of degradation.

|

Model X150 Details |

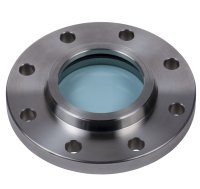

Model X150: Lowest Long-Term Ownership Cost

For lowest long-term cost of ownership, our X150 sight glass is the clear choice.

All gasket seals eventually leak. Since industrial flanges do not wear out with use,

the true long-term cost of sight glass ownership is the cost of leak maintenance, not the cost of initial acquisition.

Our X150 sight glasses feature our proprietary seals applied on the side walls of tempered Pyrex, soda lime, or fused

quartz lens in order to minimize this cost.

When a leak eventually develops due to the plastic flow of the seal, simply tighten the flange bolts a little.

The fact that these units are sealed on the side walls means that bolt force is NOT applied directly on the glass surface. Tightening flange bolts on sight glass windows that seal on the glass face is dangerous; eventually, the bolt force will crush the glass and cause a catastrophic failure. The cost of such a failure will greatly exceed the acquisition costs of the sight glass window. Therefore, all vendors recommend pre-emptive, scheduled replacement of glass lens and gaskets.

The side wall sealing of X150 virtually eliminates this danger of crushing the glass while tightening the flange bolts, enabling simple resealing by tightening of the flange bolts. Instead of pre-emptive replacements, parts should be replaced when visual inspection reveals some concrete reason for replacement, such as scratched glass lens or seals that have been visibly degraded. X150 flanges are investment-castings, available in carbon and stainless steel grades.

|

Model L Flange Details |

Model L Flange: For More Demanding Installations

Some plants and installations mandate that every fitting installed be made of forgings.

Others require that fittings carry Factory Mutual test certifications. The Model L Flange fills those niches. Its design is identical to the X150, and its components interchange with those of X150 of the same size. The only difference is that the stress bearing flange is forged instead of cast. Units with laminated lenses carry Factory Mutual certification.

|

|