Assembly Instructions

This unit was assembled at the factory and is ready for installation. The sight glass should be visually checked for any possible damage during shipping. After the unit has been installed, heated and pressurized several times, the cap screws holding the retainer cap in place should be checked for tightness.

if the lens or the seal in the sight glass needs to be replaced after the unit has been in operation, it is suggested that the seal be replaced each time, and the lens replaced if there are any visual defects in the glass. When installing parts, refer to steps (A) thru (L).

- (A) Shut down the operating vessel so there is no pressure in the system where the sight glass is operating.

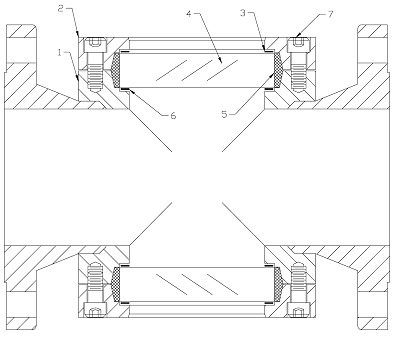

- (B) Remove the cap screws (7) holding the retainer cap (2) in place and then remove the retainer cap (2).

- (C) Remove the top cushion gasket (3).

- (D) Remove the lens (4) and seal (5) surrounding the periphery of the lens as a one piece assembly.

- (E) Remove the bottom cushion gasket (6).

- (F) Clean the interior of the body and the retainer cap.

- (G) Place the new bottom cushion gasket (6) into position.

- (H) Install the new lens (4) and the seal (5) surrounding the periphery of the lens as a one piece assembly, by placing it on top of the bottom cushion gasket (6) in the cavity of the body (1). Next place the top cushion gasket (3) on top of the lens as shown.

- (I) Place the retainer cap (2) on the body using the down pin (NOT SHOWN) to align the cap in the correct position.

- (J) Insert the socket head cap screws (7) and tighten across diameters.

- (K) The unit has been designed to compress the seal sufficiently, therefore, the cap and the body may not achieve metal to metal contact.

- (L) After the unit has been heated and pressurized several times the cap screws should be checked

for tightness.