Corrosive chemical processes are housed

in tanks, reactors, and other enclosures that are protected against corrosion from their process

fluids. Stainless steel, higher cost super alloys, and/or coatings are used to confer the necessary protection to

the wetted components. PPC offers the following circular flange mounted sight glasses to address the need to observe such processes

as economically as possible.

Unit Price Starting from $213.00

Model L Flange Details |

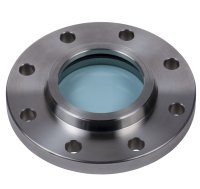

Model L Flange: Lowest Cost for Hazardous Applications

The Model L Flange features our proprietary side wall sealing without exposing any metal to the process fluid;

only the tempered Pyrex or soda lime glass and the seal are wetted by the process fluid. Therefore, 300 series stainless steel flange will accommodate most applications.

If there is a requirement that the flange be made of a certain super-alloy material to match the rest of the process structure,

Model L flange can be fabricated out of such materials; its simple design results in the minimal use and machining of expensive super-alloys for any given application. If the process fluid is hazardous, leak maintenance becomes an important safety issue. Unfortunately, all sealing mechanisms that rely on plastic deformation, including all gaskets, will eventually leak. This is why all gaskets are supposed to be replaced on a scheduled basis, preferably before they develop leaks. Unlike most other sight glass windows on the market, Model L features a side wall sealing mechanism that allows the user to safely reseal a leaky unit by tightening the flange bolts a little. |

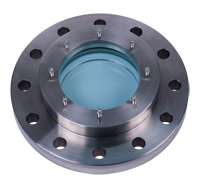

Model I Flange Details | Model I Flange: Hazardous, High Pressure, High Temperature ApplicationsThe Model I Flange is the most capable sight glass window unit on the market; no other commercially available unit can sustain service conditions like 1,100 degrees Fahrenheit (with fused quartz lens-tempered

Pyrex and soda lime lens are rated to 450F) and 600 PSI (more upon request) while offering super alloy level of corrosion resistance at a reasonable cost. Like the Model L, the Model I uses side wall sealing, but adds a metallic insert and a separate compression ring to apply sealing stresses independent of flange bolts. The wetted parts include only the glass, sealing packing, and the insert made of the required (super) alloy; stress bearing flange structure is not wetted, allowing the use of lower cost materials. The independent compression ring allows for easy in-situ resealing with virtually no danger of over-stressing the glass window. Since the sealing compression is independent of flange bolts, resealing can be accomplished with even more finesse than possible with Model L. For extremely corrosive applications, a PTFE insert can be used instead of a metallic insert, such that no metal is in contact with the process fluid. |

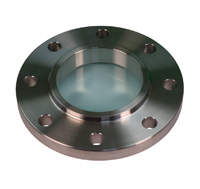

Model S Flange Details | Model S Flange: Simpler Unit for Moderately Corrosive but Safe ApplicationsA number of processes involve fluids that are moderately corrosive but not dangerous, ranging from brine to dilute organic acids, etc. In such cases, moderate leaks do not become safety issues, and it is possible to use simpler designs safely. Model S Flange offers the lowest initial acquisition cost by using the industry standard gasket seal on the glass face, without any wetted metal parts. (However, if long term maintenance costs are taken into account, the Model L listed above will usually be more economical.) |

|